Home

>

Old West Iron Blog: Craftsmanship, Heritage & Hand-Forged Expertise

>

How Old Are Square Head Bolts?

How Old Are Square Head Bolts?

by Maddison Mellem on May 08, 2025The Origins, History, and Enduring Value of the Square Head Bolt

When it comes to historic craftsmanship and durable construction, few fasteners are as iconic — or as enduring — as the square head bolt. Its unmistakable profile shows up everywhere from 1800s timber frames and railroads to vintage farm equipment and cast iron machinery.

But how old are square head bolts, really? And why have they lasted when so many other hardware styles have come and gone?

Let’s take a closer look at their history, their practical advantages, and how high quality modern replicas are keeping this essential hardware alive today for builders, designers, and preservationists alike.

The Early Origins of the Square Head Bolt

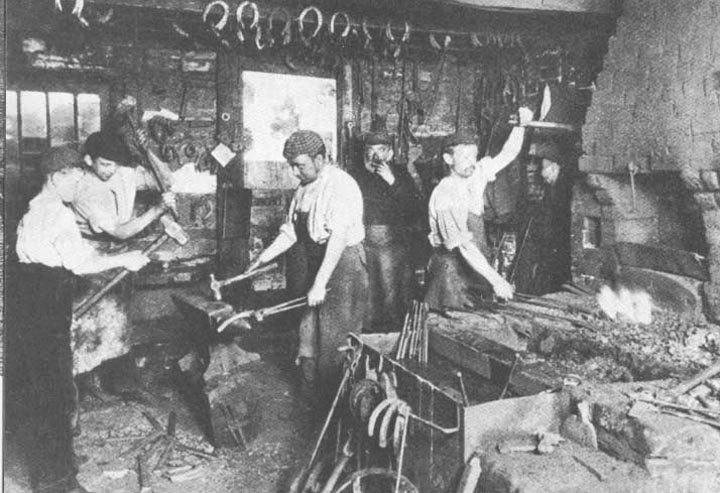

The origins of the square head bolt date back to the 18th century, during a time when blacksmithing was the primary method of manufacturing fasteners. Before automated threading and cold-heading machinery, bolts were made one at a time. Blacksmiths forged square heads because they were relatively easy to shape and offered superior grip when tightened with the rudimentary hand tools of the time — like open-ended spanners or monkey wrenches.

By the early 1800s, square head bolts became increasingly common as industries expanded. From timber bridges and mills to the booming railroad industry, these bolts served as the go-to solution for applications requiring strength and durability.

The shape wasn’t ornamental — it was functional. And it worked.

Why Square Heads Were a Smart Solution

There were several reasons why square head bolts became the standard for so long:

1. Ease of Forging

Square heads could be shaped efficiently with hammer and anvil, long before machines were available to create uniform round or hex heads.

2. Tool Compatibility

A square profile gave blacksmiths, carpenters, and machinists more surface area to grip. When wrenches were crude and sometimes hand-made themselves, the square bolt head was easier to hold, align, and torque down.

3. Rustic Appeal with Practical Strength

The angular profile allowed the user to apply more torque than a round head without slippage. They were often used in timber framing, railroad trestles, wagons, and barns — all places where a strong, reliable fastener was non-negotiable.

Today, many designers intentionally seek out this design for its heritage feel and rugged, industrial aesthetic. Builders recreating that vintage charm turn to the square head bolt for both strength and style.

Square Head Bolts in 19th and Early 20th Century America

As the United States pushed westward in the 1800s, settlers and builders brought square head bolts with them — using them in mining equipment, ranch fences, telegraph poles, and even early factories. From covered bridges in New England to cattle corrals in Texas, the square head bolt became a standard piece of hardware across every industry.

Even after hex heads became easier to mass-produce in the 20th century, square bolts remained in circulation for heavy-duty industrial applications, military use, and agricultural equipment. They remained in regular use through World War II, and even today, many restoration projects rely on high quality modern replicas to replace their originals with historically accurate precision.

A Return to Form: Why Square Bolts Still Matter Today

So why are builders, blacksmiths, and designers still seeking out this style?

The square head bolt represents authenticity — not just in how things were built, but in the pride that went into those builds. Today, people reach for square bolts for the same reasons craftsmen did 200 years ago: reliability, function, and a no-nonsense visual style.

You’ll find rustic bolt hardware in all kinds of modern projects:

-

Timber Frame Homes – A perfect structural fastener that blends seamlessly with rough-sawn beams

-

Reclaimed Wood Furniture – Adds antique charm and rugged appeal to handcrafted tables, benches, and beds

-

Historic Restorations – Museums, barns, mills, and historic buildings require period-correct fasteners

-

Barn Door Hardware & Gates – For projects that demand both strength and historical detail

-

Railroad, Mining & Industrial Replicas – Used in displays and practical applications replicating 1800s engineering

-

Outdoor & Landscape Architecture – Great for pergolas, arbors, and fencing with an Old West flair

Forged for the Future: Modern Replicas with Historical Integrity

At Old West Iron, we take that legacy seriously. Our square head bolt collection includes exacting high quality modern replicas forged in the spirit of original blacksmithing practices. Each piece is made to order in the USA and available in a wide range of sizes, finishes, and textures.

Whether you’re trying to match hardware on a 150-year-old barn or adding rugged detail to a new build, our rustic bolt selection ensures the perfect fit.

-

Available in custom lengths and diameters

-

Threaded for wood or metal applications

-

Offered in finishes like raw iron, flat black, antique pewter, and oil-rubbed bronze

-

Can be paired with matching square nuts, washers, and fasteners

-

Great for both indoor and exterior use

Conclusion: Why Square Head Bolts Still Hold Up

The square head bolt may be old — but it’s far from obsolete. Its straightforward form, reliable performance, and historical value make it a mainstay in restoration work and a favorite among builders with an eye for detail.

It’s not just a fastener. It’s a piece of history — still doing the job it was made to do centuries ago.

Looking for the real thing?

Explore Old West Iron’s full selection of square head bolt options and find high quality modern replicas of this essential rustic bolt, made by hand and built to last.

western bolts, old west blacksmith, hand-forged iron, historical blacksmith, architectural history